Learn the very best Practices for Effective Foam Control in Industrial Applications

Learn the very best Practices for Effective Foam Control in Industrial Applications

Blog Article

The Duty of Foam Control in Enhancing Item Top Quality and Performance

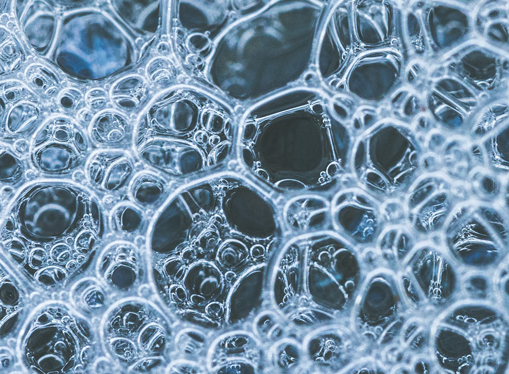

Foam control is an often-overlooked yet vital part in the quest of product top quality and operational performance across diverse sectors. This discussion will certainly check out the multifaceted influence of foam on both product honesty and production procedures, increasing important inquiries regarding the strategies that can be used to optimize foam control.

Comprehending Foam Formation

Foam development is a complex sensation that can significantly affect item high quality and functional efficiency throughout different industries. Comprehending these variables is crucial for handling foam properly.

The liquid's thickness and surface tension play crucial roles in foam stability. Surfactants, for example, can reduce surface stress, advertising bubble formation yet also improving foam security, which can be bothersome in certain applications. Mechanical anxiety, temperature level variations, and the existence of contaminations can worsen foam generation, making it crucial to keep an eye on these aspects during production processes.

Industries such as food and drink, drugs, and chemical production should be especially cautious regarding foam control. By comprehending the underlying systems of foam formation, companies can carry out targeted methods to mitigate its effects, therefore maintaining functional performance and making certain regular item efficiency.

Effect On Product Top Quality

The visibility of foam can dramatically endanger item high quality across various industries. In manufacturing procedures such as food and drink, pharmaceuticals, and cosmetics, excessive foam can lead to irregular item formulas. As an example, in food production, foam might catch air, impacting texture and taste, which can inevitably change consumer assumption and satisfaction.

Furthermore, foam can hinder the harmony of finishings and paints, resulting in flaws like bubbles and unequal coatings. In pharmaceutical applications, foam can disrupt the accurate application of liquid medicines, potentially influencing therapeutic efficiency and client safety. These high quality issues not just diminish completion product's charm yet can likewise lead to expensive recalls and damages to brand online reputation.

Furthermore, the visibility of foam can complicate quality assurance steps, making it tough to achieve exact dimensions and regular results. Efficient foam control not just reduces these risks but likewise boosts overall item top quality by guaranteeing that formulas fulfill stringent market criteria. By purchasing foam control techniques, business can guard their products, enhance client fulfillment, and maintain an one-upmanship in the market.

Functional Obstacles From Foam

Effective operations in different markets can be drastically disrupted by the existence of foam, which presents numerous obstacles throughout manufacturing procedures. Foam can prevent blending and response times, impeding the efficiency of chemical processes. In industries such as food and beverage, foam formation can result in incorrect fill levels, leading to product waste and disparities in packaging.

In settings where health is paramount, such as pharmaceuticals and food processing, foam can complicate cleaning protocols, creating hidden reservoirs for contaminants. This not only raises quality concerns but also can lead to conformity concerns with governing criteria.

In addition, the emotional effect on operators can not be neglected; excessive foam can create a disorderly workplace, causing reduced morale and productivity. In recap, resolving the functional try this website difficulties positioned by foam is crucial to maintaining performance and item high quality in various sectors.

Strategies for Reliable Foam Control

How can sectors successfully reduce the challenges postured by foam? Efficient foam control strategies are crucial for improving item high quality and operational effectiveness. One primary technique is making use of defoamers, which are chemical representatives designed to remove or reduce foam development. Selecting the proper defoamer requires a detailed understanding of the specific process problems and the products included.

Along with chemical solutions, process optimization plays a critical role in foam administration. Industries can analyze and adjust specifications such as blending rate, temperature, and pressure to lessen foam generation. Applying equipment modifications, like installing foam-breaking gadgets or adjusting storage tank style, can better aid reduce foam levels.

Regular monitoring and analysis of foam habits within production processes are likewise important. Using sophisticated sensing units and analytics can supply real-time information, permitting for prompt treatments and changes. Team training is just as important; guaranteeing that employees are educated about foam dynamics and control techniques can lead to proactive foam monitoring.

Instance Researches and Sector Applications

While several sectors deal with special difficulties related to foam control, case researches disclose that customized techniques can considerably enhance both product top quality and functional efficiency. In the pharmaceutical sector, for circumstances, a leading maker carried out a customized foam control strategy that minimized foam development during fermentation procedures. This technology not just enhanced yield by 15% however additionally lessened contamination risks, ensuring greater product honesty.

Similarly, in the food and drink market, a significant dairy products producer faced excessive foam throughout pasteurization - Foam Control. By introducing a specialized antifoam representative, they decreased handling time by 20%, which directly converted to enhanced throughput and lowered energy intake. The application of foam control determines ensured regular product appearance and taste, enhancing brand commitment

In the chemical production industry, an instance research study highlighted the effective application of foam control in wastewater treatment procedures. The execution of a real-time Discover More tracking system permitted operators to change antifoam dose dynamically, leading to a 30% decrease in chemical use and enhanced effluent top quality.

These case research studies highlight the diverse applications of foam control throughout sectors, emphasizing its essential click here to find out more function in boosting item quality and operational performance.

Final Thought

In verdict, effective foam control is essential to improving item top quality and operational efficiency across different sectors. By addressing foam formation, companies can alleviate the adverse influences on formulations, texture, and dosing accuracy. Executing targeted foam administration approaches not just lowers processing delays and waste but also reinforces equipment reliability. Eventually, prioritizing foam control adds to enhanced efficiency, securing brand name online reputation, and increasing customer fulfillment, highlighting its relevance in quality control within making procedures.

Foam control is an often-overlooked yet important part in the pursuit of item high quality and operational efficiency throughout diverse industries. Team training is equally vital; making sure that workers are educated regarding foam dynamics and control techniques can lead to aggressive foam monitoring.

While lots of industries encounter special challenges connected to foam control, case researches expose that customized methods can significantly boost both product top quality and operational effectiveness (Foam Control). In the pharmaceutical sector, for circumstances, a leading manufacturer carried out a custom foam control method that reduced foam development throughout fermentation processes.In verdict, effective foam control is indispensable to enhancing product top quality and operational effectiveness throughout various markets

Report this page